Pipe-Line Reinforcing Mesh Crimped Galvanized 25.4 mm x 67 mm Mesh x 190.5 mm Strips

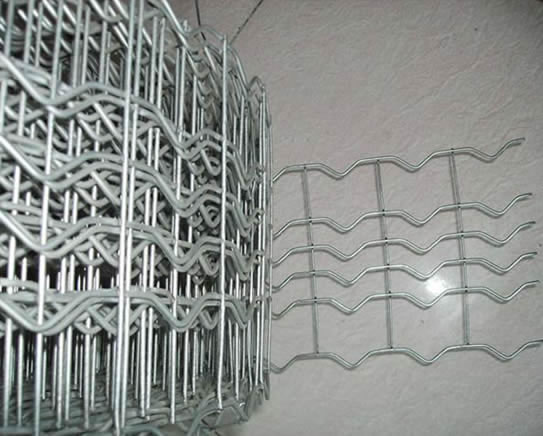

Pipeline Reinforcing Mesh is crimped wire mesh in coils used for subsea pipelines concrete encasement.

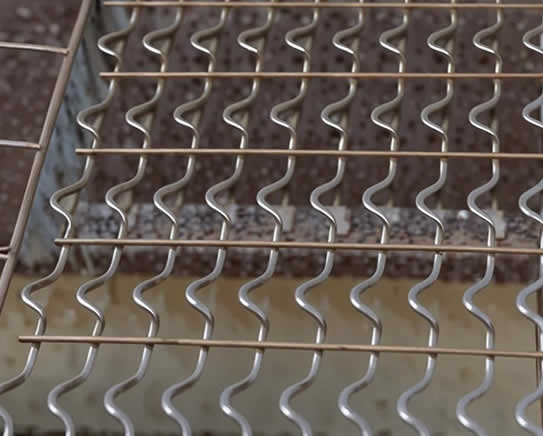

It is made by deeply pre-crimped steel wire welded in special pattern. Heavily galvanized, Crimped Welded Wire Mesh is widely used in concrete weight coating for subsea/onshore pipelines.

We supply pipeline reinforcing weldmesh to UAE, USA, Canada, Vietnam, Peru, Turkey and other countries.

Specifications of pipe-line reinforced mesh

Material: Low Carbon Steel Wire.

Wire Form: Crimped

Surface: Heavy zinc galvanized, epoxy coated

Mesh Construction: Spot welded

Standard: ASTM 810 standard, ASTM 185, A82 standard.

Custom specifictions: Available.

The material of pipe-line reinforced mesh is low carbon steel wire pre crimped with galvanized coating. Galvanized wire can be cold galvanized wire or hot dipped galvanized meeting the ASTM standard. The line wires are deeply crimped to facilitate the concrete application. The reinforcing mesh is firmly spot welded.

The reinforcing mesh is supplied in rolls or strips for light gauges, flat panels for heavy types.

Functions: Welded crimped mesh in pipeline concrete coating can reinforce the concrete layer, enhancing the structural integrity and resistance to cracking and impact during pipeline installation and operation.

Welded Wiremesh Reinforcement Galvanized Crimped Conforming To ASTM 810

Wire Mesh Reinforcement For Pipe Line in Marine Engineering and Construction Projects

Pipeline Reinforcing Welded Mesh Galvanized Crimped 25.4mm x 67mm hole x 190.5mm Width x 165m Length

Specifications:

Width: 7½ Width (190.5 mm)

Mesh Size: 67 mm X 25.4 mm

Number Of Line Wire/Width: 8

Wire Dia: 2.10 mm (Line Wire) X 1.70 mm (Cross Wire)

Roll Length: 165 M

Quality: ASTM A810, "Standard Specification for Zinc-Coated (Galvanized) Steel Pipe Winding Mesh."

Pipeline Reinforcing Welded Mesh Galvanized Crimped 25.4mm x 67mm hole x 190.5mm Width x 160m Length

Specifications:

Width: 7½ Width (190.5 mm)

Mesh Size: 67 mm X 25.4 mm

Number Of Line Wire/Width: 8

Wire Dia: 2.20 mm (Line Wire) X 1.80 mm (Cross Wire)

Roll Length: 160 M

Quality: ASTM A810, "Standard Specification for Zinc-Coated (Galvanized) Steel Pipe Winding Mesh."

Welded Wire Fabrics for Continuous Concrete Coating for Canal Pipelines (NPS24, NPS36, NPS42)

Welded Wire Fabric for Continuous Concrete Coating (CWC)– NPS24 Pipeline

Applicable Pipe Size: NPS 24 (Approx. OD 610 mm)

Concrete Coating Thickness: 60 mm

Mesh Aperture: 67 × 25.4 mm

Wire Diameter: 3.0 mm

Mesh Width: 500 mm

Mesh Length: 2.0 m

Surface Treatment: Hot-dip galvanized (≥100 g/m²)

Rebar Grade: ASTM A1064 Grade 60

Application: Reinforcement of concrete-coated canal transmission pipelines

Welded Wire Fabric for Continuous Concrete Coating – NPS36 Pipeline

Applicable Pipe Size: NPS 36 (Approx. OD 914 mm)

Concrete Coating Thickness: 90 mm

Mesh Aperture: 100 × 50 mm

Wire Diameter: 4.0 mm

Width: 800 mm

Length: 2.5 m

Surface Treatment: Hot-dip galvanized (≥100 g/m²)

Rebar Grade: ASTM A1064 Grade 60

Application: Structural mesh layer in precast or in-situ pipeline concrete coatings

Welded Wire Fabric for Continuous Concrete Coating – NPS42 Pipeline

Applicable Pipe Size: NPS 42 (Approx. OD 1067 mm)

Concrete Coating Thickness: 110 mm

Mesh Aperture: 100 × 50 mm

Wire Diameter: 5.0 mm

Panel Width: 1000 mm

Panel Length: 3.0 m

Surface Treatment: Hot-dip galvanized (≥100 g/m²)

Rebar Grade: ASTM A1064 Grade 60

Application: Large-diameter canal pipelines reinforcing

Need more information about Concreate Reinforcing Products? Contact us now.